We speak to Kevin Wolter, Director of Business Development at Invio Automation, about its proven automation expertise that has accelerated global businesses across a vast range of industries for over 60 years.

SETTING THE FUTURE IN MOTION

Global investment in the North American manufacturing industry has never been higher, encouraging many companies to focus on reshoring their production and supply chain to the US, whilst government incentives have dramatically encouraged domestic production.

On top of this, industry trends such as labor shortages, increased wages, and a greater desire for improved production consistency and quality have driven manufacturers in the country to implement robotics and manufacturing automation more widely across their organizations.

This presents the industry with an opportunity to source and analyze more data, particularly given the recent rise of the Internet of Things (IoT) – also known as Industry 4.0 – and the evolution of digitalization, which allows for greater real-time monitoring, predictive maintenance, and process optimization.

Within this context, the main focus of Invio Automation (Invio) lies in supplying state-of-the-art manufacturing automation and robotics solutions to its customers, regardless of the project’s size or scale.

Designing, implementing, and sustaining automation services for some of the largest operations in the world, the company permeates a number of key industries, including medical device and life sciences, CleanTech and renewable energy, mobility, industrial, logistics, and much more.

“Invio designs, implements, and sustains automation for operations large and small across the world. Our company history dates back 65 years, and we continue to evolve. We take pride in truly partnering with our customers to solve big challenges by exploring, testing, and customizing the latest manufacturing technology,” opens Director of Business Development, Kevin Wolter.

“The company exists to contribute and participate in one of the great macroeconomic trends of our time – the increased role of robotics and automation in our daily lives.

“Our work takes us into hundreds of factories and product development organizations every year and we proudly help our customers build meaningful products in healthcare, renewable energy, and transportation,” he adds.

Invio’s founding principles are twofold. Firstly, it strives to serve as the preferred global automation partner in industries that meaningfully benefit the lives of others. Secondly, it employs hundreds of engineers, skilled tradespeople, and manufacturing professionals domestically in an effort towards that goal.

Each industry is served across seven production sites in the US, with its primary base located in the Midwest region of the country.

MULTIPLE SOLUTIONS FOR MULTIPLE INDUSTRIES

Providing practical and proven solutions for a vast range of industries, the company works with customers to fundamentally understand and take their ideas through an entire lifecycle, manufacturing these products with industry-leading robotics and automation capabilities.

“A lot of our customers are looking to improve quality and reproducibility while reducing labor,” informs Wolter.

Operating for over 40 years in the medical devices sector, the company possesses more than 500 team members in the US, a third of which are in an engineering role and actively partake in the technological elements of a project.

“As a mechanical and electrical engineer, I find it really engaging to see both elements integrated into these products,” he adds.

Alongside the manufacturing of medical devices, the organization conducts warehousing and logistics practices, whilst a large portion of its business supports the automotive and industrial markets with custom tooling and lift-assist services, as well as top-quality automated guided vehicles (AGVs) and automated mobile robots (AMRs) that can transport heavy pallets throughout customers’ warehouses and production areas.

One particular focus of Invio is known as Factory of the Future Consulting, whose workforce serves as a consultancy agency for their clients. After performing plant-wide greenfield and brownfield automation assessments, the company utilizes production modeling and 3D simulations to help customers determine where automation can have the most cost-effective impact on their return on investment (ROI) and production processes.

As such, Invio’s efforts ensure reliability and digital innovation across the entire manufacturing process.

“Each automation aspect, from factory floor to end-stage enterprise resource planning (ERP), is informed by a certain level of data, which in turn impacts the wider supply chain of any given product,” Wolter highlights.

“In the future, I foresee the same team presenting customers with augmented reality (AR) and virtual reality (VR) models of their facilities.”

RELIABLE END-TO-END SERVICE

Invio stands out in the US automation market due to its dedicated willingness to work with customers throughout their entire manufacturing journey, ranging from smaller operations to complex robotic systems.

“Historically, many of our new customers came to us after other automation vendors had declined requests to quote, because their projects were too intricate or technically complicated. However, we actively engage with these types of customers as we have the experience and capability to undertake complicated, high-precision developments,” Wolter imparts.

“Our customers often return to us after we’ve solved their most difficult automation problems, providing support for their entire manufacturing process. The target is to become their preferred automation vendor.”

Therefore, it is mutually beneficial for the company to support clients in the early stages of their automation journey so that they can become the go-to manufacturer for the entire process.

As such, Invio has built an enviable reputation for small, high-precision products. In the medical devices space, this typically involves the likes of insulin pumps, cardiac implants, catheters for heart disease and stroke support, as well as many other micro-manufacturing processes.

With a core market focus and an established manufacturing process, the company has developed a set of flywheels that enable it to provide incredible solutions and services for customers.

“We continue to reinvest in this approach and cross-pollinate applications across our core markets. For example, we assess who else requires needle bending capabilities to generate a list of customers we can address.

“Meanwhile, for our engineering expertise, we develop specific applications within a certain industry that we can add to our toolbox. This allows us to improve our operations and build bigger machines around that expertise,” Wolter explains.

Furthermore, Invio is committed to providing ‘white glove service’ for all customers, as it aims for the highest degree of professionalism, responsiveness, proactive customer engagement, and support throughout the lifecycle of an automation project.

“Recently, a potential early-stage prospect mentioned that, while they were looking at several potential automation partners, Invio provided the best customer service. We are looking forward to engaging with that customer more formally very soon.”

A critical element of Invio’s long-standing success is its loyal partner and supplier relationships, which keep projects flowing beyond everyday operations.

“This has been one of the first times in my career that I have found such a strong collaboration between my organization, suppliers, and customers,” Wolter expresses.

As the company continues to establish its name in the market, Invio works with suppliers to set up joint customer visits, where it can recommend potential suppliers for preferred automation vendors.

MEDICAL DEVICE AND LIFE SCIENCES (MDLS) CAPABILITIES

As Invio continues to expand its MDLS focus into new geographic markets, such as the Midwest and Minnesota’s Medical Alley, it successfully leverages its 40 years of experience in the space to support the broader sales, engineering, and operations teams in the industry and related automation and design principles.

“Personally, it has been incredible to work with experts and thought leaders, and I continue to be amazed by the knowledge base they have created and their willingness to share their experience,” Wolter expresses.

“As we build our team, we continue to expand our market presence and add major MDLS customers.”

Within this division of the company, Invio’s central desire is to improve patient healthcare for its customers’ end users.

The opportunity to impact the lives of real people on a global scale is significant. The company’s patented hypotube and needle bending technology was developed to support the rapidly growing diabetes market. Globally, there are 400 million people diagnosed with Type 2 diabetes (T2D), making Invio’s patented needle bending technology increasingly critical.

Therefore, the company’s systems help provide insulin for diabetics and manufacture highly technical catheters, guidewires, sensors, and on-body pumps. Regarding the latter, the equipment is used to create a key part of an insulin pump that is placed on the user to help treat their condition.

“The benefit of having this needle, which has a very unique, spring-loaded shape, is that when it’s time to pump insulin, the needle inserts a cannula that we have also manufactured. This creates a port for the application of insulin into the body,” details Wolter.

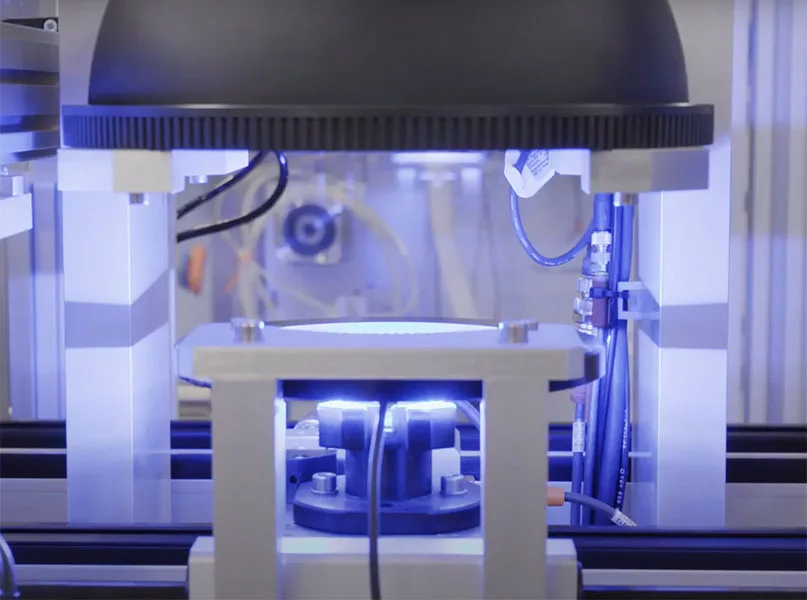

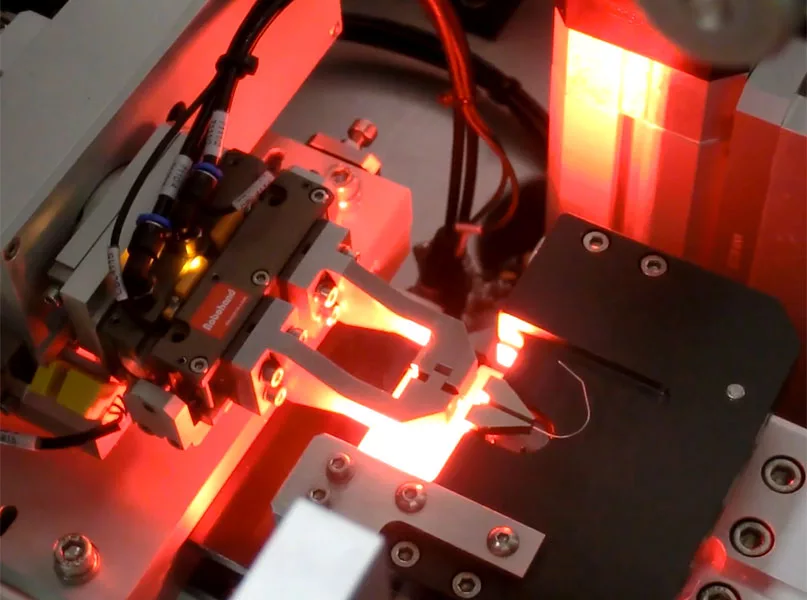

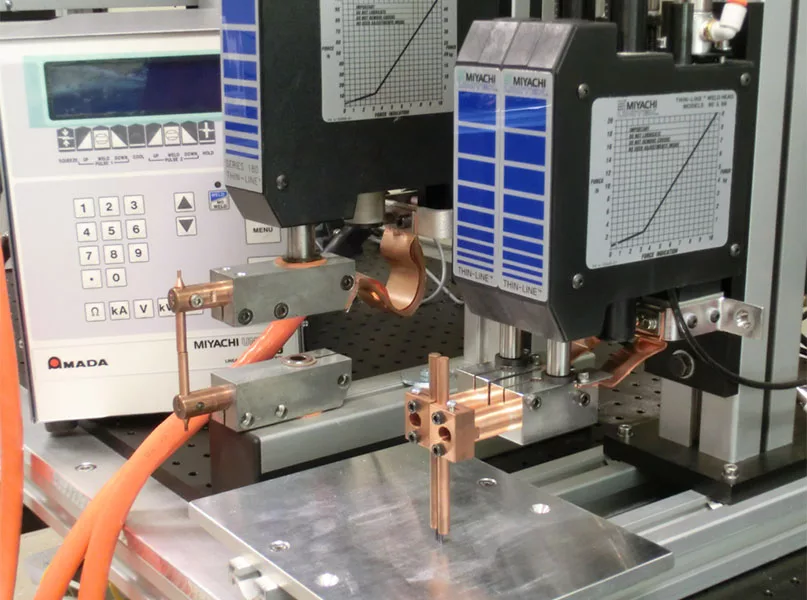

Invio’s patented needle bender is capable of bending a drug delivery needle to as small as 1/10,000th of an inch in outside diameter without blocking the drug delivery of the needle. The machine utilizes a high-precision camera and servo motors to ensure the proper needle orientation and position in real-time throughout the manufacturing process. Once at the desired angle, the machine bends both sides of the needle to create a specified shape without occluding it.

The standard needle bending module is capable of producing a uniquely shaped needle every six seconds.

However, needle bending is just one stage of the insulin pump product that Invio manufacturers, demonstrating the fact that a small, simple solution can lead to the production of an entire process and an all-encompassing solution.

BLOOD COLLECTION DEVICE

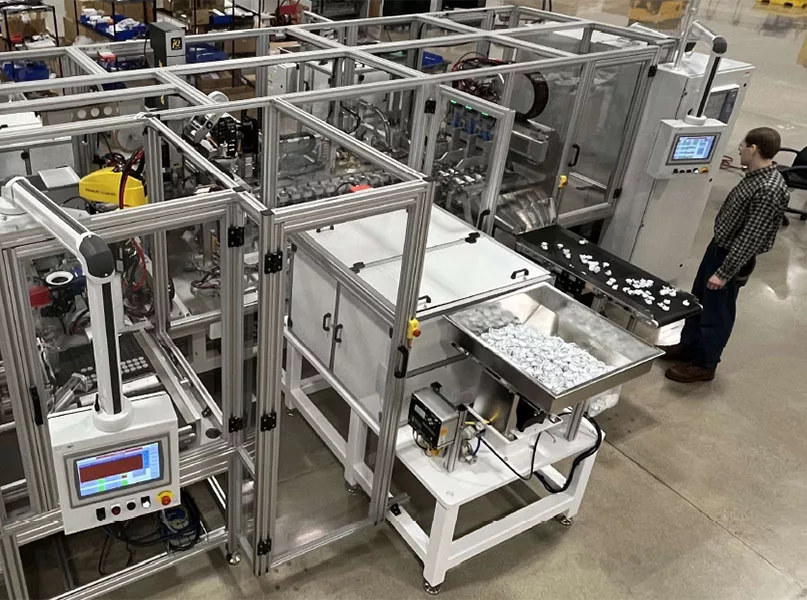

Invio recently developed an automation project that produces a blood culture collection device, which can be used by medical professionals to draw blood more efficiently and avoid incorrect blood test results.

The machinery for the blood collection device produces 15 parts per minute, translating to 900 units an hour.

“We were able to design, develop, and deliver an incredible piece of equipment for our customer in approximately nine months on our first major MDLS project in our new Minnesota facility,” Wolter proudly tells us.

“This is thanks to our ability to leverage our incredible local engineering capabilities and the vast MDLS expertise available from the broader Invio team.”

In order to further its specialized offerings, the company is currently building an applications lab in Minnesota, which will showcase the key technologies and tools that it integrates into its machines every day. These include robots, ultrasonic and laser welders, laser markers, lead testers, and much more.

“The intention is for the facility to serve as an additional engineering resource for our customers as they continue to develop these incredible technologies. Additionally, the lab will be an effective marketing tool for our partners and suppliers who can bring their customers on-site as they work through their technical evaluations,” Wolter elaborates.

“The staff here are amazing – one year ago, I joined Invio and was fortunate to BE PART OF a team of highly motivated professionals who understand their role within a collective and take pride in getting the job done”

Kevin Wolter, Director of Business Development, Invio Automation

EXPERTS IN AUTOMATION

The extensive size of Invio’s workforce means that it can productively collaborate across a plethora of industries and applications to brainstorm the best solutions for its customers.

“The staff here are amazing – one year ago, I joined Invio and was fortunate to be part of a team of highly motivated professionals who understand their role within a collective and take pride in getting the job done. I believe we have cultivated an organization that encourages individuals to speak up with recommendations for continuous improvement,” Wolter proudly comments.

The company recognizes staff that go beyond the call of duty with established reward programs and monthly newsletters that highlight hard-working employees, who also have the chance to win prizes.

“I also acknowledge individuals on a more personal level or in small group settings, as it presents an opportunity to further my relationships with the team in a meaningful way,” affirms Wolter.

As Invio continues to expand its business, both organically and through acquisitions, it remains focused on its core mission to be committed to engineering advanced industrial solutions that enhance quality of life.

Another major priority for the business is the aggressive alignment of the company’s seven production sites across one common platform.

However, one of the most important things for Wolter is that the company and its employees continue to learn and have fun.

“Throughout my 12 months in the role, our team has been incredibly engaged and excited, and I learn more from them every day,” concludes Wolter.