After making an impact in manufacturing, 3D printing has now proven itself as an invaluable asset within the healthcare industry.

REGENERATIVE MEDICINE

Medical technology (MedTech) in its many forms serves the healthcare industry in prevention, diagnosis, monitoring, treatment, and care, and as the industry is always evolving, another transformation is underway.

3D printing is the latest driving force behind how medical treatments are moving forward. Although the technology has been around for a while, it is infiltrating hospitals as a way of delivering more affordable prosthetics, especially in the US where medical bills are rising exponentially.

Prosthetics is not the only part of healthcare to benefit from the increased scale of supply enabled by 3D printing and secure its future in MedTech, as the technology will eventually be able to provide organs, cutting the need for human donors. For now, it is used for the development of surgical instruments and anatomical guides, alongside creating straight-to-patient products such as replacement limbs.

Despite how 3D printing is aiding the medical profession and patients alike, certain aspects of the process such as 3D bioprinting are still in the development stage, and the printers themselves are not regulated.

Ultrafine particles (UFPs) are released during the printing process, when there is no proper ventilation in the machine. If inhaled, UFPs can cause adverse health effects, including an increased risk of asthma, heart disease and strokes.

However, the positive implications far outweigh the negatives of exposure to UFPs. Moreover, 3D printing for medical purposes is set to become a USD$32 billion industry by 2025, and that number is expected to almost double by 2030.

HEALTHCARE SOLUTIONS

Presently, three areas of the healthcare industry utilise 3D printing: learning and anatomical replicas, surgical tools, and prosthetics.

One of the largest areas of application in 3D printing is the fabric of anatomical replicas by using patient scan data to enhance the diagnosis of illnesses, clarify treatment decisions, and even practice surgical interventions in advance of the actual treatments.

The technology can also produce anatomical models to help the doctors visualise difficult anatomies when using minimally invasive techniques. Furthermore, the models can explain upcoming medical procedures to patients and their families, and assist in precisely sizing medical devices.

3D printing can also create surgical tools with precision and accuracy to follow a patient’s unique anatomy. The tools can place restorative treatments such as screws, plates and implants, resulting in better postoperative results. As prosthetics can be time consuming and expensive, mainly due to replacements or alterations, printing technology can change this by being used regularly to produce patient-specific components.

Known as additive manufacturing, the recent advances in 3D printing have led to stronger and lighter products, along with reduced waiting times and lower costs. Due to the individualised nature of healthcare, using printing technology is the perfect solution for the industry.

BRINGING PRINTING TO LIFE

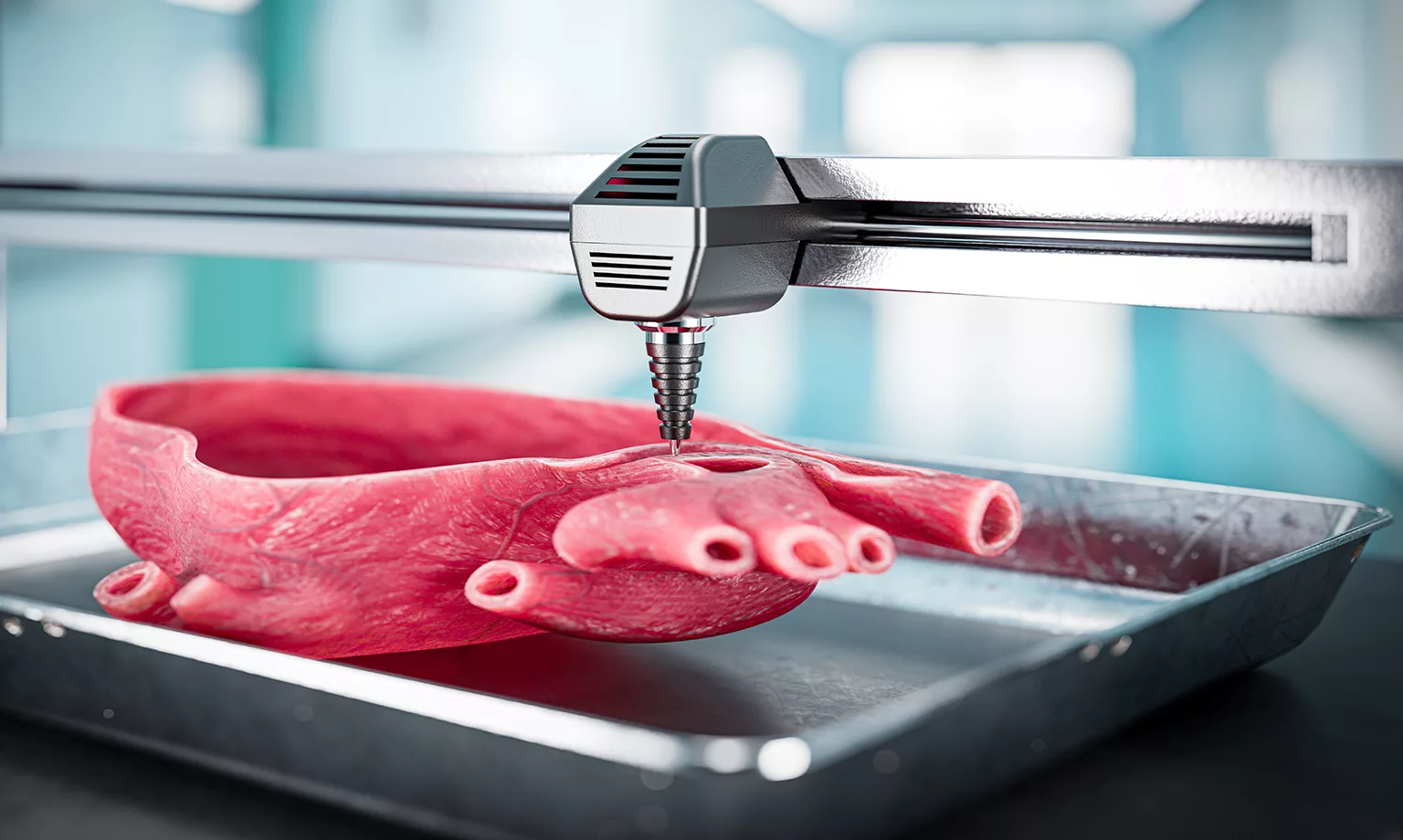

Another way in which MedTech innovation is making a difference in the healthcare industry is with 3D bioprinting. Except, rather than changing lives, it is saving lives, and although the manufacturing process is similar to 3D printing, bioprinters print with cells and biomaterials, creating organ-like structures that let living cells multiply. This leap in medical progress has been achieved through a fusion of biology and engineering.

The aim of 3D bioprinting is to deliver previously unavailable treatment options to patients by regenerating lost organs and functions, and to address medical needs unmet by conventional surgery and therapies.

According to the Health Resources and Services Administration (HRSA), nearly 106,000 Americans are currently on the waiting list for an organ donor, and 17 die each day while waiting. Therefore, a 3D printing process that uses the patient’s own cells to grow organs would not only reduce the waiting list, but also dramatically decrease the risk of organ rejection, eliminating the need for lifelong immunosuppressive medication.

3D printed organs have not been approved for human use yet, however, transplants using the technology may soon be a reality. Researchers in the medical field have put together a timeline of 20 to 30 years before full-size 3D printed organs can be transplanted into humans, meaning donor hearts and livers will not be needed.

So far, flat structures such as multi-layered skin, bones, muscle structures, retinal tissues, tubular structures such as blood vessels, and hollow organs such as bladders have been 3D printed. A heart would require billions of cells; ergo, until biologists have a breakthrough, the waiting list for organ donors will stay in its present condition.

The process begins by generating cells to bioprint, which are then instructed to become organ specific cells. The cells are then rendered into a living, printable ink (bioink), which involves mixing them with materials like gelatin or alginate to create a paste-like consistency. The substance is then loaded into a syringe and placed into a printer cartridge and deposited using the patient’s medical scans, which involves a layer-by-layer approach and 3D scaffolds.

The tissue is often connected to a pump which drives oxygen and nutrients through it. In time, the tissue develops on its own and function naturally increases.

With techniques under continuous development, providing both short-term and long-term solutions, MedTech no longer seems like science fiction, but looks like the future of healthcare.